-

$

The offered fiber optic cable is a made-to-order product. You can order a minimum of 12 km of cable. The production and delivery time is approximately one month.

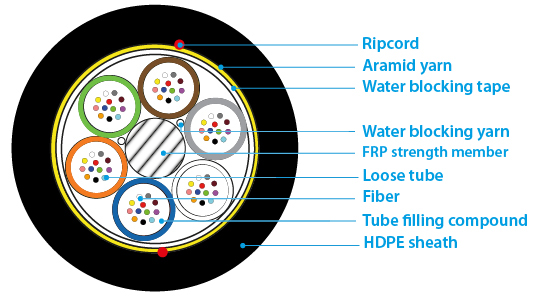

YOFC ADSS-XOTKtsdD is a self-supporting ADSS-type fiber optic cable designed primarily for aerial installations. It is equipped with 72 G.652.D (singlemode) fibers arranged in 6 tubes (12 fibers per tube). All tubes are stranded around a central strength member – a 2.4 mm diameter FRP rod. Additionally, the manufacturer has applied peripheral reinforcement in the form of aramid yarns, providing the cable with a tensile strength of 4 kN. As a result, the maximum span length under NESC Heavy conditions reaches up to 100 meters, making the cable suitable for demanding environments. The outer diameter of the cable is approximately 10.4 mm, and the weight is 85 kg/km. The outer sheath is made of HDPE, with a nominal thickness of 1.5 mm.

The offered product is best suited for aerial installations, especially along main routes, in locations where a durable cable with low-attenuation fiber is required. The ADSS-XOTKtsdD can also be used in telecommunication ducts.

Cable Construction

The cable features a multi-tube construction, with tubes stranded around a central strength member – a 2.4 mm diameter FRP rod. This design provides rigidity and prevents the fibers from moving or shifting due to temperature fluctuations.

The entire structure is additionally reinforced peripherally with Kevlar (aramid) yarns to increase tensile strength. Two ripcords are embedded in the sheath to facilitate easy stripping.

Aerial Installation

The offered product is primarily designed for use in aerial installations. It has a maximum tensile strength of 4 kN and can span up to 100 meters under NESC Heavy conditions. The cable can also be successfully used in telecommunication ducts.

72 Fibers (6 Tubes, 0 Fillers)

The ADSS-XOTKtsdD contains 72 singlemode G.652.D fibers arranged in 6 tubes (12 fibers per tube). The outer diameter of the cable is 10,4 mm, and its weight is 85 kg/km.

The sheath is made of durable HDPE with a thickness of 1.5 mm. The cable is designed for outdoor installations and has a CPR classification of Fca.

G.652.D Fiber (Singlemode)

The fiber optic cable is equipped with G.652.D singlemode fibers. This fiber type is characterized by low attenuation: ≤ 0.35 dB/km at 1310 nm and ≤ 0.21 dB/km at 1550 nm. These low losses are achieved at the expense of reduced flexibility compared to G.657.A2 / G.657.B3 fibers.

Thanks to these parameters, cables with G.652.D fibers are best suited for main routes. In such applications, lower flexibility is not a disadvantage, while for long-distance transmissions, the total attenuation will be significantly lower than with other fiber types.

Specifications

| YOFC ADSS-XOTKtsdD 72 (4 kN) | ||

| Fiber quantity | 72 | |

| Fiber type | G.652.D (Singlemode) | |

| Tube quantity | 6 | |

| Fiber count / tube | 12 | |

| Tube outer diameter | 2,2 mm | |

| Conetral strength member material | FRP | |

| Central strength member diameter | 2,4 mm | |

| Water blocking material | Water blocking yarn and tape | |

| Peripheral strength member material | Aramid yarn | |

| Outer sheath material | HDPE | |

| Outer sheath color | Black | |

| Outer sheath thickness | Nominal: 1.5 mm | |

| Ripcord quantity | 2 | |

| Ripcord color | Red | |

| Cable diameter | ~ 10,4 mm | |

| Cable weight | ~ 85 kg/km | |

| Max allowable tension | 4000 N | |

| Crush | 1500 N/100mm | |

| Color code |

TIA-598 1: Blue 2: Orange 3: Green 4: Brown 5: Grey 6: White 7: Red 8: Black 9: Yellow 10: Violet 11: Pink 12: Aqua |

|

| Operation temperature | -40ºC~+70ºC | |

| Installation temperature | -40ºC~+70ºC | |

| Storage temperature | -40ºC~+70ºC | |

| Static bending radius | 10 times the cable diameter | |

| Dynamic bending radius | 20 times the cable diameter | |

| Mechanical, Physical and Environmental Test Characteristics | ||

|---|---|---|

| Test type | Test Method | Requirements |

| Tension | IEC 60794-1-21-E1 Load: According to 3.5 Sample length: Not less than 50m. Duration time: 1min. |

Additional attenuation: ≤ 0.05 dB after test No damage to outer jacket and inner elements |

| Crush | IEC 60794-1-21-E3A Load: According to 3.5 Duration of load: 1min |

Additional attenuation: ≤ 0.05 dB after test No damage to outer jacket and inner elements |

| Impact | IEC 60794-1-21-E4 Radius: 300 mm Impact energy: 10J Impact number: 1 Impact points: 3 |

Additional attenuation: ≤ 0.1 dB after test No damage to outer jacket and inner elements |

| Repeated bending | IEC 60794-1-21-E6 Bending radius: 20 *D Cycles: 25 Load: 150N |

Additional attenuation: ≤ 0.05 dB after test No damage to outer jacket and inner elements |

| Torsion | IEC 60794-1-21-E7 Cycles: 10 Length under test: 1 m Turns: +/-180° Load: 150N |

Additional attenuation: ≤ 0.1 dB after test No damage to outer jacket and inner elements |

| Water Penetration | IEC 60794-1-22-F5 Time: 24 hours Sample length: 3m Water height: 1m |

No water leakage |

| Temperature cycling |

IEC 60794-1-22-F1

|

The change in attenuation coefficient shall be less than 0.05 dB/km. |

| Other parameters | According to IEC 60794-1 | |

Polski

Polski English

English Italiano

Italiano Español

Español Čeština

Čeština Српски

Српски Deutsch

Deutsch Ελληνικά

Ελληνικά Slovenský

Slovenský