-

€

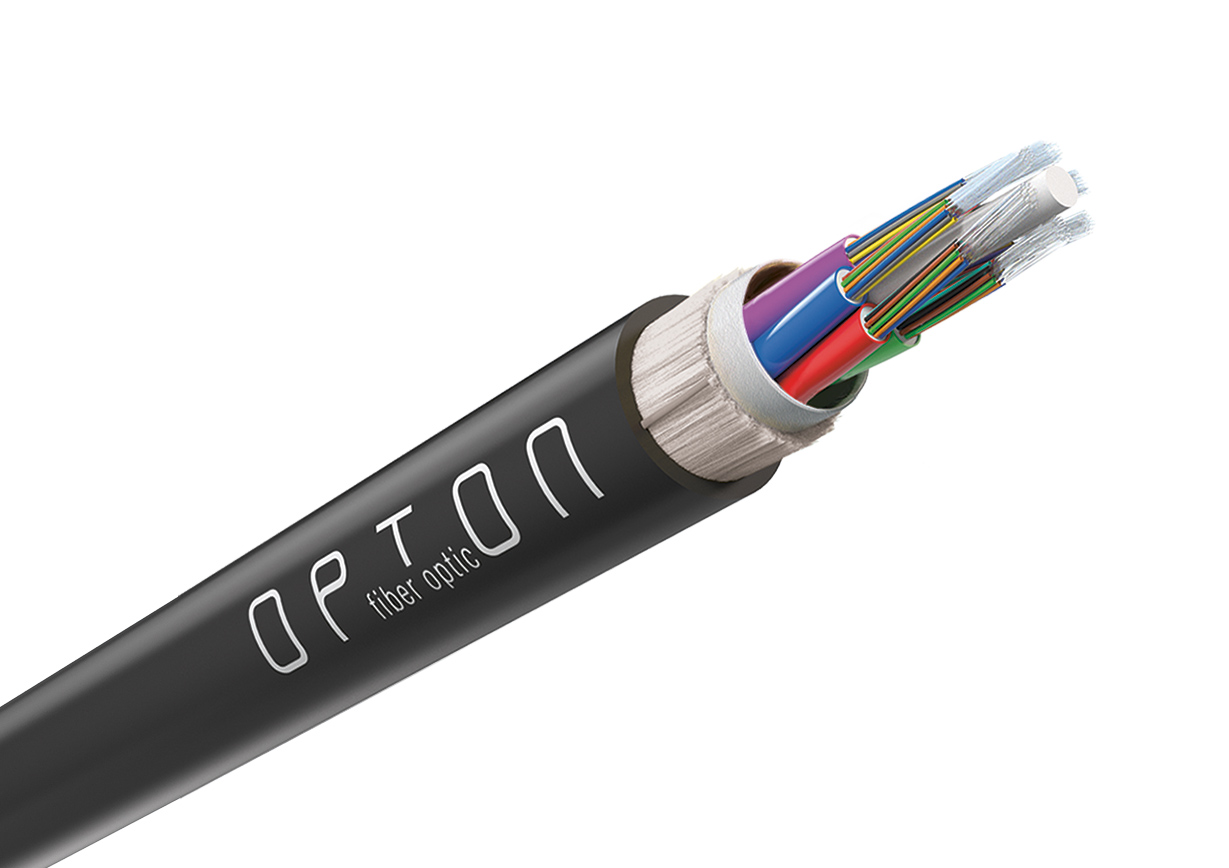

Opton Z-XOTKtsd is an optical fiber cable intended for use in teletechnical sewage system. There is a multi-tube construction, it has 96 G.652.D fibers. The fibers are placed in 8 tubes, without fillers. The tubes were twisted around a central reinforcing element - a 3 mm thick FRP rod. The whole structure has been additionally reinforced with fiberglass. Thanks to this, the maximum tension force is 2500 N.

The outer shell is made of black HDPE plastic. The thickness of the entire cable is about 9,4 mm and the thickness of the sheath itself is about 1 mm. The tubes were surrounded by a blocking water tape, which further seals the whole cable. The outer shell has 2 ripcords for easy cable peeling.

Features

- fiber optic cable for teletechnical sewage system;

- 96 G.652.D fibers;

- multi-tube construction (8 tubes with 12 fibers per tube, without fillers);

- central reinforcing element - FRP rod 3 mm thick;

- maximum pulling force - 2500 N;

- fiberglass reinforcement;

- diameter 9,4 mm.

Specifications

| Z-XOTKtsdDb 96J | |

| Application / Construction | |

|---|---|

| Application | Duct installation |

| Configuration | Loose tubes with 12 optical fibers per tube, filled with thixotropic compound Stranded loose tubes Central strength member made of fiber reinforced plastic (FRP, PE coated if necessary) Cable strand: dry, water blocking yarns and tape Peripheral strength member: glass yarns Outer sheath: Black HDPE, two red ripcords under the outer sheath |

| Temperature range |

Storage and transport: -40 to +70°C Installation: -10 to +60°C Operation: -40 to +70°C |

| Standards |

IEC 60793-1 IEC 60793-2 IEC 60794-3-10 |

| Dimensions | |

| Number of fibers | 96 |

| Loose tubes x fibers | 8x12 |

| Filler number | 0 |

| Loose tube Ø | 1,8 mm |

|

CSM Ø (central strengthening element) |

3,0 mm |

| Outer sheath thickness | 1,0 mm |

| Outer diameter (± 5%) | 9,4 mm |

| Cable weight (± 15%) | 79 kg |

| Mechanical Properties | |

| Max. tensile load | 2500 N |

| Crush resistance /10 cm | 1000 N |

| Bending radius | Installation: 20x cable-Ø, Operation: 10x cable-Ø |

| Colour Code & Marking | |

| Fiber Colors |

1 - red 2 - green 3 - blue 4 - yellow 5 - white 6 - gray 7 - brown 8 - violet 9 - turquoise 10 - black 11 - orange 12 - pink |

| Tube Colors |

1 - red 2 - green 3 - blue 4 - yellow 5 - white 6 - gray 7 - brown 8 - violet 9 - turquoise 10 - black 11 - orange 12 - pink |

| Optical fiber | |

| Standard | ITU-T. G.652D |

| Fiber attenuation |

@ 1310 nm ≤0.36 dB/km @ 1550 nm ≤0.22 dB/km |

| Mode field diameter (MFD) | 9.2 ± 0.4 µm @ 1310 nm |

| Zero dispersion wavelength | 1300~1324 nm |

| Zero dispersion slope | ≤0.092 ps/nm² ∙km |

| Polarization mode dispersion (PMD) | ≤0.2 ps/√km |

| Cable cut-off wavelength | ≤1260 nm |

| Macro bending loss .. 100 turns Ø50 mm |

@1550 nm ≤0.05 dB @1625 nm ≤0.10 dB |

| Coating diameter (Colored) | 250 ± 15µm |

| Cladding diameter | 125 ±1µm |

| Core/clad concentricity error | ≤0.6µm |

| Cladding non-circularity | ≤ 1.0% |

| Proof stress | ≥ 0.69Gpa |

| Test Methods | |

| Tensile strength IEC 60794-1-2 E1 |

Tensile strength: see Point 3

Fiber strain: ≤0.6% |

| Crush resistance IEC 60794-1-2 E3 |

Crush: see Point 3

△α ≤0.05dB after test |

| Impact IEC 60794-1-2 E4 |

Impact energy: 1J, R = 300mm

△α ≤0.05dB after test |

| Repeated bending IEC 60794-1-2 E6 |

Bending radius: 20x cable Ø

△α ≤0.05dB after test |

| Torsion IEC 60794-1-2 E7 |

Sample length: 2m

△α ≤0.05dB after test |

| Bend IEC 60794-1-2 E11 |

Mandrel diameter: 20x cable Ø

△α ≤0.05dB after test |

| Temperature cycling IEC 60794-1-2 F1 |

-40℃→+70℃

△α≤0.1dB/km |

| Water penetration IEC 60794-1-2 F5 |

Sample length:3m, water column height:1m

No water leakage |

Polski

Polski English

English Italiano

Italiano Español

Español Čeština

Čeština Српски

Српски Deutsch

Deutsch Ελληνικά

Ελληνικά Slovenský

Slovenský